Chinese Professional Production Custom Cardboard Packaging Shipping Boxes Underwear Corrugated Paper Board Box Cartons – Shengjing

Chinese Professional Production Custom Cardboard Packaging Shipping Boxes Underwear Corrugated Paper Board Box Cartons – Shengjing Detail:

What are the testing items for corrugated boxes?

Corrugated boxes are widely used in the outer packaging of commodities due to their characteristics and environmental advantages, and play an important role in the transportation, preservation and sales of commodities. In the process of use, the carton is required to achieve a certain degree of firmness and durability.

At present, the fierce market competition makes the carton manufacturers continue to improve the production process and management to obtain great profits, which makes the carton users encounter more or less quality problems in the process of using the carton, such as The collapse and rupture of cartons after stacking caused many unnecessary losses.

In order to avoid such a situation and produce qualified carton products, it is necessary to test the corrugated box, so that the production process of the corrugated box can be effectively controlled. Therefore, it is of great significance to correctly understand and understand the testing items and testing methods of corrugated boxes.

1. Overview of appearance quality

Qualified cartons require clear printed patterns and handwriting, no broken lines and missing patterns, consistent pattern chromaticity, bright and bright, and small printing position error. It is also required that the box body joints are standardized, the edges are neat, and the corners are not overlapped.

2. Moisture content

The so-called moisture content refers to the moisture content in the corrugated base paper or cardboard, expressed as a percentage.

Corrugated base paper has certain pressure resistance, tensile resistance, puncture resistance and folding resistance. If the moisture content is too low, the paper will be too brittle, easily broken when corrugated, and the folding resistance will be poor.

3. Cardboard thickness

The thickness of corrugated cardboard refers to the vertical distance between the upper and lower sides of the corrugated cardboard under a certain pressure, in millimeters. It is one of the inspection items for the appearance defects of the carton, and directly affects the edge compressive strength, puncture strength and compressive strength of the cardboard. .

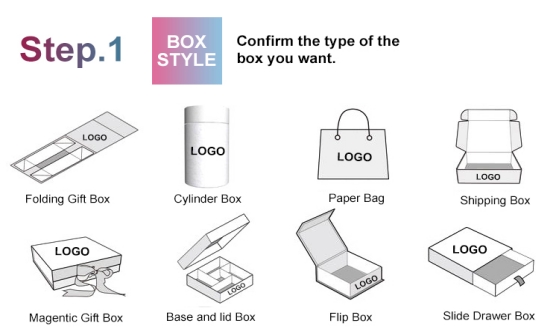

| Item Name | Corrugated Packaging Box |

| Material | Corrugated Board |

| Size | Customization |

| Color | Customization |

| Shape | Customization |

| Sample time | 3 days |

| Production time | 7 -10 days after everything is confirmed |

| PACKING | Flat packing ,around 50-60pcs/ctn |

| SAMPLE | Plain sample is free , printed sample need some cost charge |

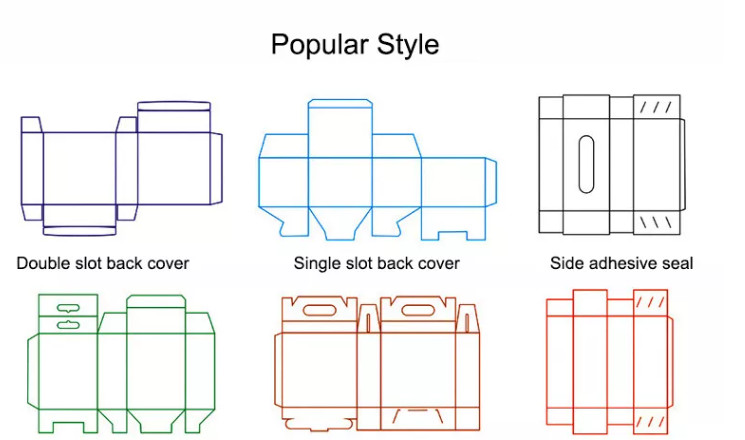

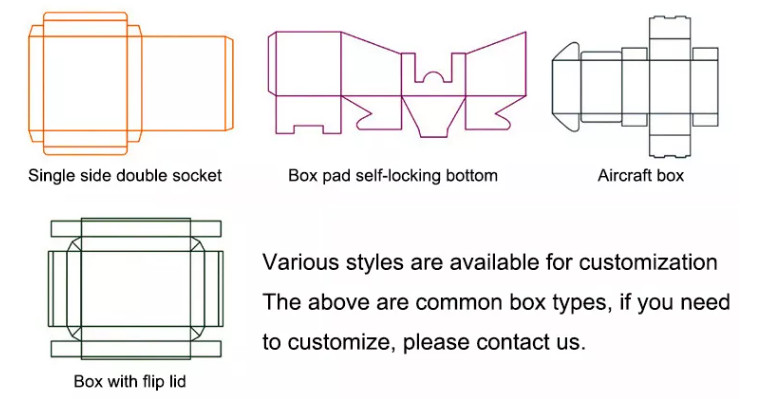

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously changing economic and social needs for Chinese Professional Production Custom Cardboard Packaging Shipping Boxes Underwear Corrugated Paper Board Box Cartons – Shengjing , The product will supply to all over the world, such as: Seattle, Mongolia, Venezuela, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.